What is 3D Printing?

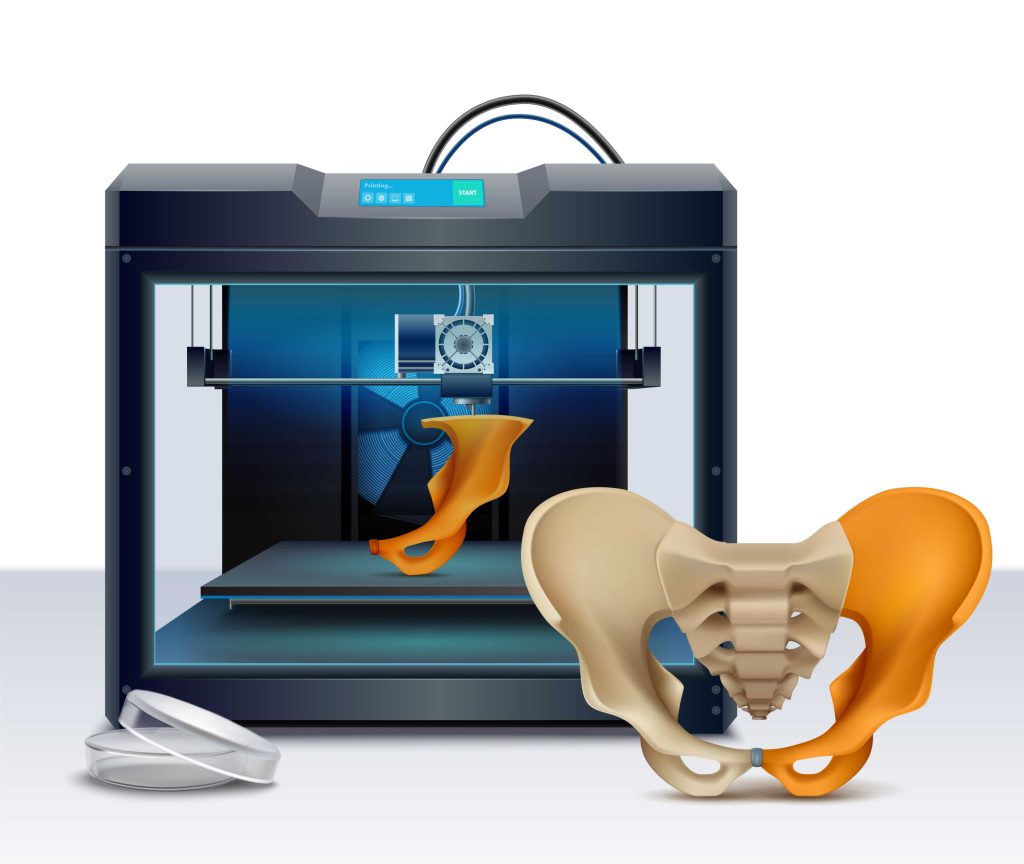

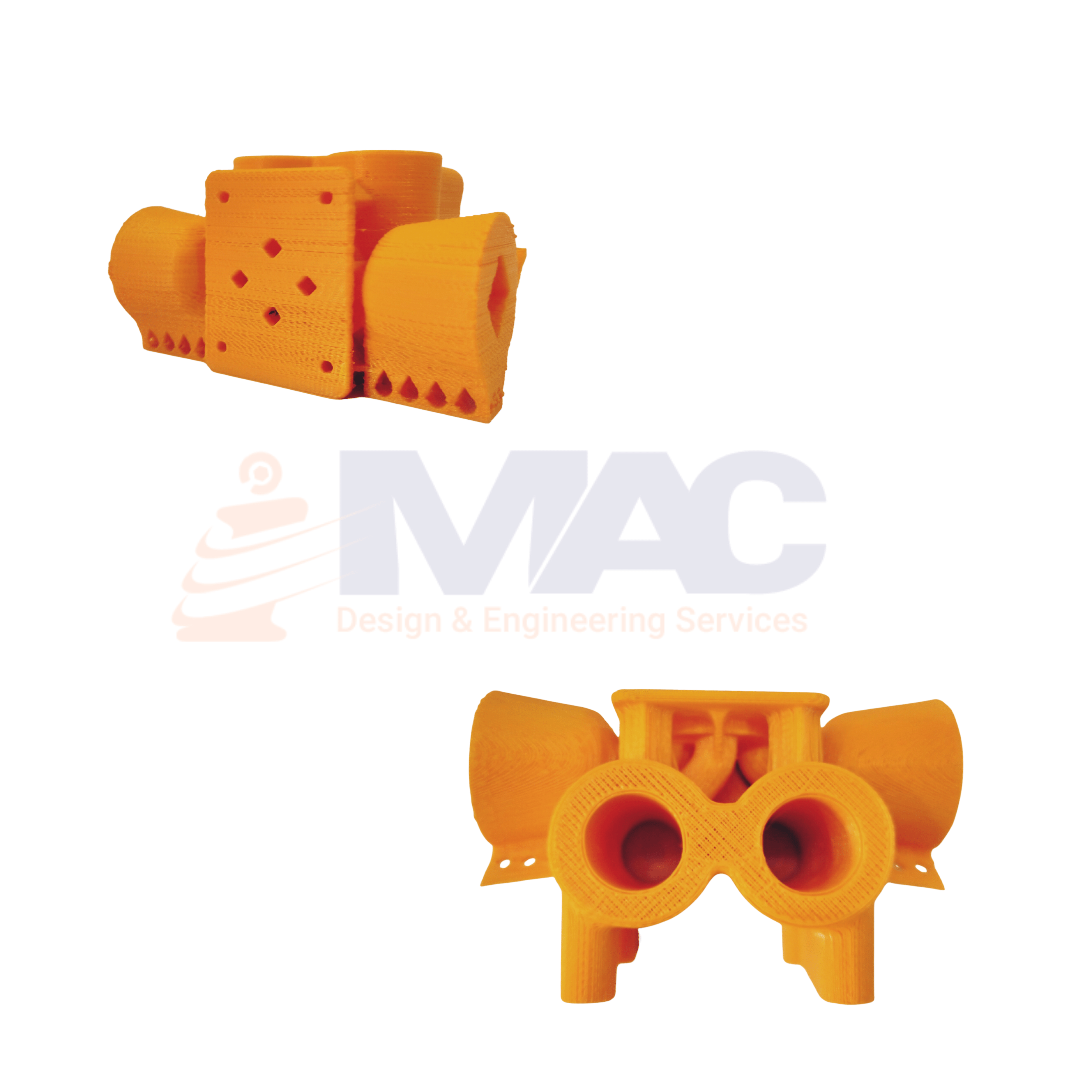

3D Printing is a cyclic manufacturing process to create three-dimensional objects layer-by-layer directly from 3D CAD model. it also enables the constructions and the manufacturing of a high stable light weight structure as well as the industrial components that cannot be produced using any conventional system.

Learn More >