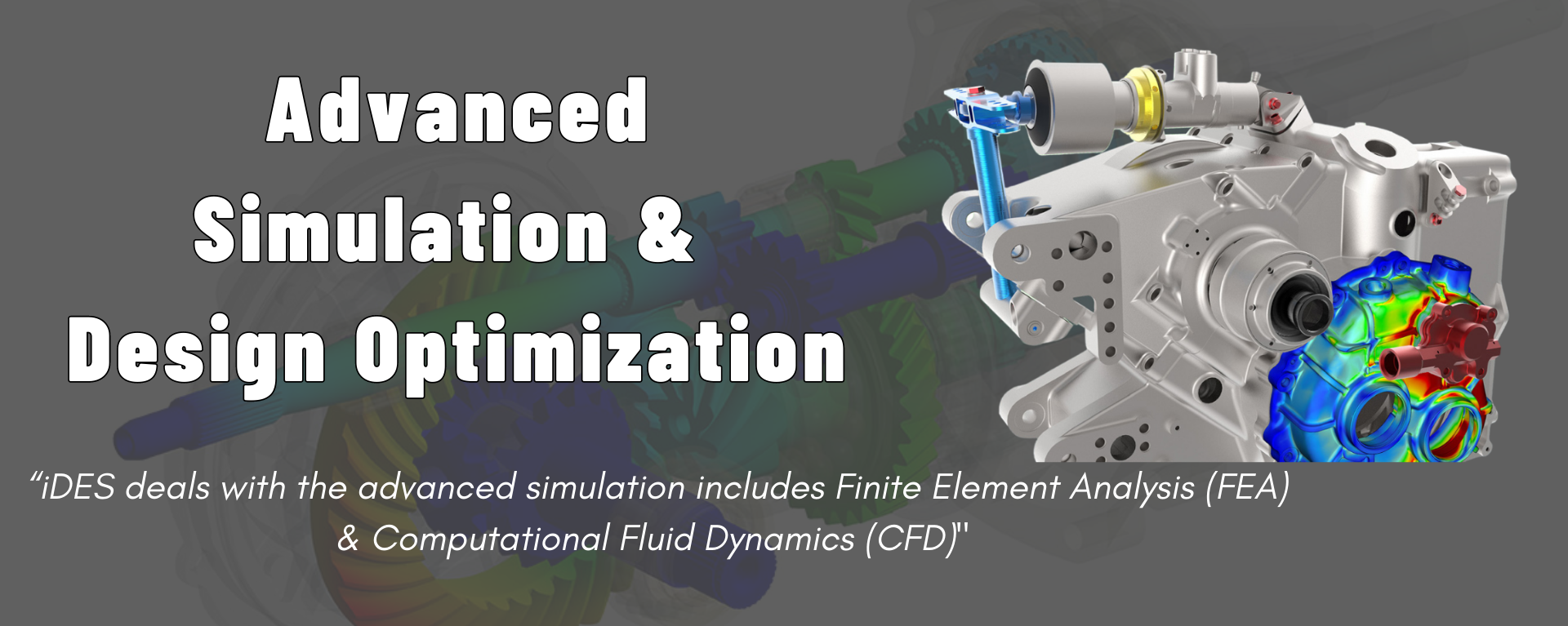

Imac designs deals with advanced simulations which includes Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD).

Here’s a brief on FEA and CAD to give you a better idea:

Finite Element Analysis (FEA): FEA basically helps our designers to analyse multiple optional designs and evaluate pros and cons. This process helps us select the best design that can suit the product. FEA also helps us check various modes of failure where the design has the potential to improve. This reduces effort and time which leads to quick turnaround. Further, if any need for customization of design arises, our designers can easily go ahead with it by modifying the dimensions and simulating its effects on the product. Before the final production, designs are tested with FEA and given a final touch of perfection.

We have latest software’s and technologies that can analyse efficiency of the product which helps eliminate delay and dragging the process of product finalization.

Computational Fluid Dynamics (CFD): The real product or the physical structure is presented with the help of CFD. CFD basically uses numerical methods to model fluid flows. This process helps rapid integration of the system to optimize configuration for cost and efficiency, for both new prototype and an existing system. The system includes moving fluid, heat transfer and chemical reactions.