Proof-of-concept

The second stage implies creating a preliminary (draft) project, developing the requirements/specifications, and analysis of a variety of possible uses of a potential product.

Next thing that we do is we specify the prices with the companies manufacturing the required components. After we select the manufacturers, we sign a nondisclosure agreement (NDA) and receive, as necessary, additional technical data.

We then choose base components and calculate the preliminary self-cost of a product (so-called Bill of Materials or BOM). When making preliminary calculations, we take into account the cost of manufacturing batches of different volumes.

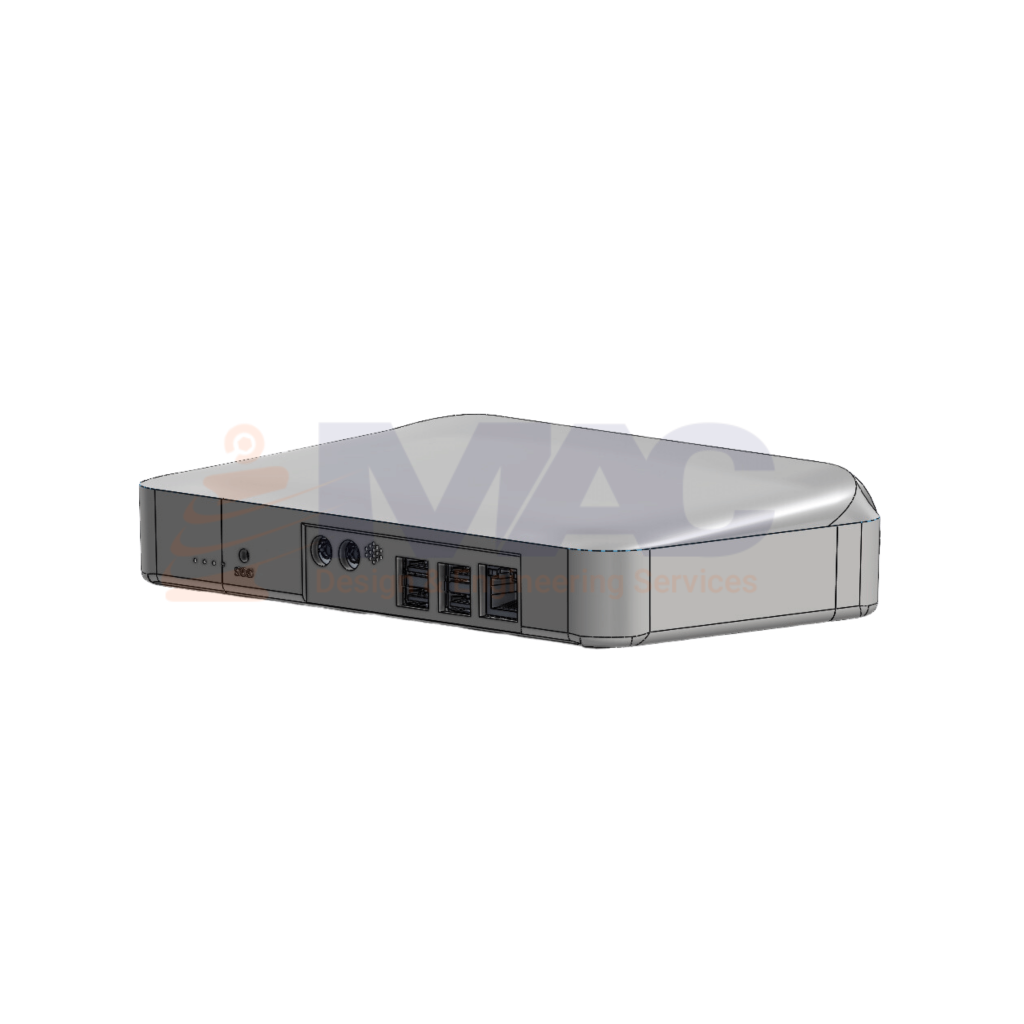

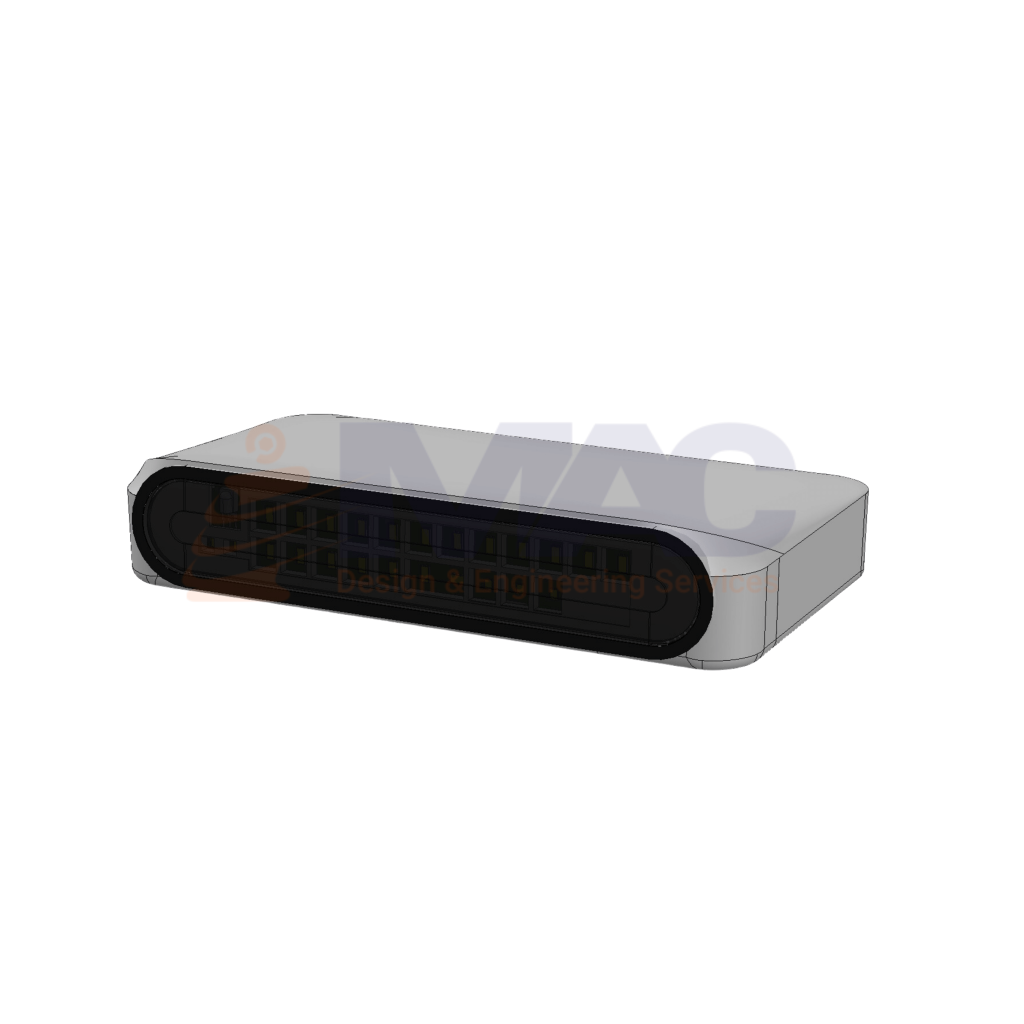

The device implementation then has to be verified by our specialists. By the end of this stage of our electronics design services, a device prototype is assembled and tested. To develop and assemble it, we purchase an evaluation kit for the chosen target platform. Our engineers evaluate the selected hardware and software technology solutions. They also assess potential weaknesses in the context of technical feasibility, the platform's performance and other essential characteristics.

As a result of this stage, we can understand whether we chose the right platform and best engineering solutions. In many cases, we also develop a limited functionality, 'desk-type' prototype of the device.